TAIHO products are developed under the following concepts.

- Focucing not only on hardware alone, but on software as well.

- Understanding not only the part, but the system as a whole.

- Responding not only to present needs, but to the future as well.

Our Products

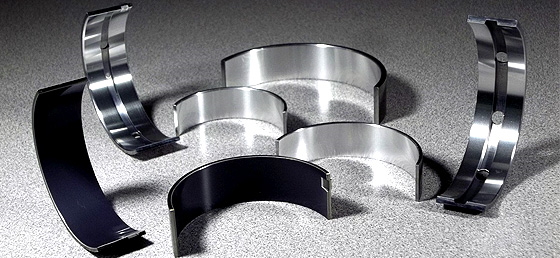

Engine Bearings

An aluminum matrix is strengthened by adding Cu (copper) as a strengthening solution treatment, and Cr (chromium) and Zr (zirconium) for precipitation hardening. In addition, reducing the Sn (tin) content and making the material lead-free prevent the lowering of the melting point caused by the eutectic reaction of Sn and Pb, and restrain the Sn construction from growing too large, to improve strength at high temperature.

A thin film overlay based on a solid lubricant, that contains no lead or other environmentally hazardous substances. It excels during the initial running-in, and eases the local contact when the engine is started. Because seizing caused by Ni (nickel) exposure, and improves seizure resistance.

Bushings

TAIHO dry bearings have been developed for the following three usages. First of all, you want to use bearings without lubricating oil completely. Secondly, you want to use bearings in a difficult place to supply lubricating oil. Thirdly, you want to use bearings in a place which lubricating oil easily becomes insufficient, although under oil lubrication. The dry bearing shows low friction characteristics even without lubricating oil, because it contains PTFE (polytetrafluoroethylene), MoS2, graphite and etc. that have self lubricating properties.

Vacuum Pumps

Vacuum pumps for diesel & gasoline vehicles. It generates negative pressure as power source of braking assistant device.

- High reliability

- High efficiency

- Miniaturization

- Low torque

- Low cost